Survey Design Model (SDM)

A single point of contact for the design and construction phases of every project

Survey Design Model (SDM)

SDM guarantees risk-averted installation of FIROTHERM panels

The onsite assembly of the FIROTHERM panels alone is already much faster than traditional construction methods. With SDM, we take final assembly into account as we model our panels, ensuring that they match perfectly to each other, tailored to the unique aspects of each building.

Because of our SDM philosophy, we are certain that when our panels arrive on-site perfectly tailored to the existing structure. All team members collaborate throughout the process to provide rapid project delivery.

Survey Design Model Breakdown

Survey

Firomar uses point cloud scans of objects or topography during the survey stage, which will later be used to design and model the panels. This process involves field scanning of the structure using laser scanners, which create point cloud files.

Design

After the site is surveyed, we move the information into our BIM software programs. The files we get off the lasers are manipulated to create images that can be layered with assemblies such as windows, doors, and walls. This allows design integration of mechanical, electrical and plumbing in 3D.

Model

The model stage takes us from design and into concept. At this stage, we put together the finishes, connections, and any other final touches that will be attributed to the panels. This ensures that the panels will be ready for immediate installation once they arrive on-site, avoiding any costly issues.

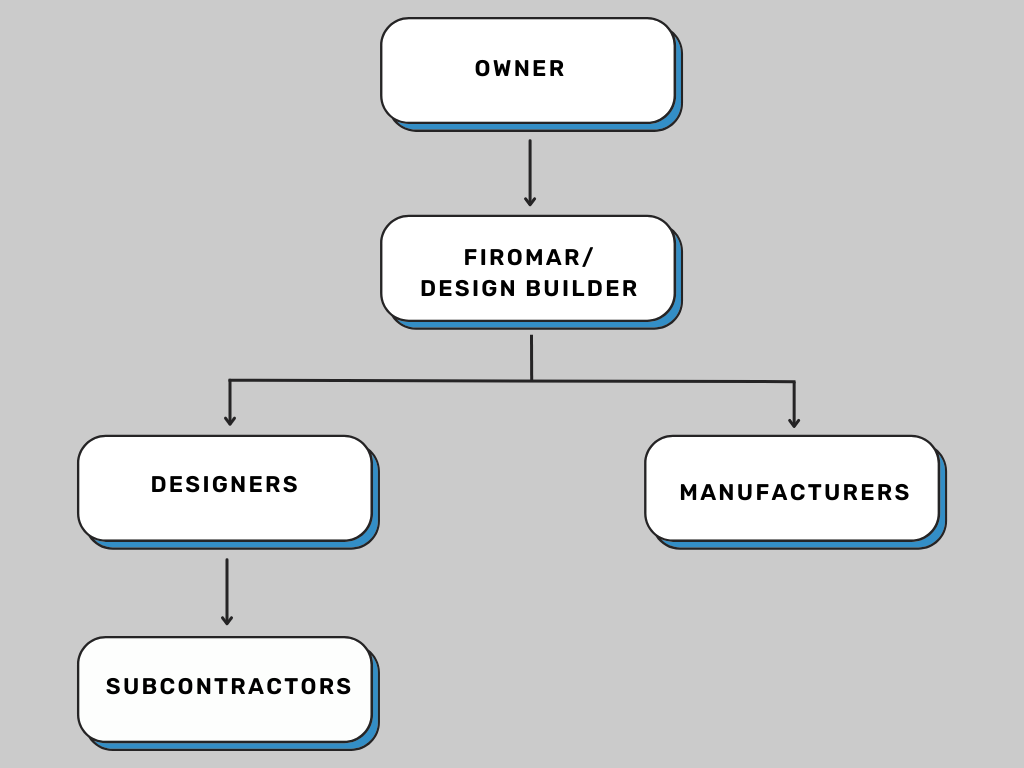

SDM Project Delivery

The owner manages only one contract with a single point of responsibility; designer, contractor and manufacturer are all on the same team. Firomar is able to provide the owner with the most simple solution available, thanks to our SDM technology.